Pulp and Paper Commodity Intelligence Platform

We provide detailed information on every pulp and paper mill in the world.

See the platform in action.

Designed by Pulp and Paper Professionals

FisherSolve is a powerful, flexible, and comprehensive business intelligence platform for professionals in the pulp and paper industry, including producers, suppliers, investors, and regulators.

The core of our pulp and paper services and solutions.

FisherSolve provides detailed information on every pulp and paper mill in the world. Access information on assets, production, operations, environmental flows, costs-of-production, carbon footprint, and much more.

Available in 10 different languages, to ensure no matter where you are located, you can take full advantage of the services this platform has to offer.

-

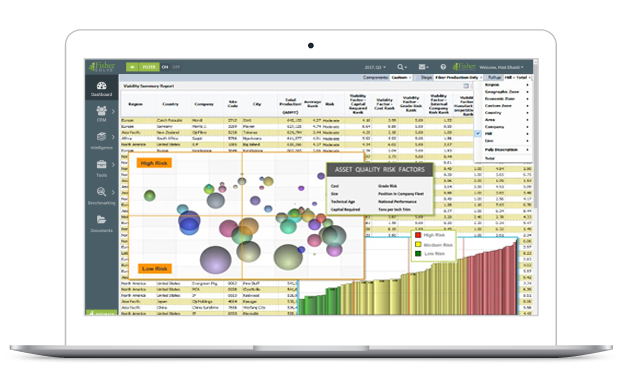

Asset Quality and Viability Index

Our Viability Module helps users predict the long-term future of pulp lines and paper machines. Its algorithms reflect what owners consider when deciding what to do with their assets.

Users gain the ability to evaluate the staying power of a given machine, mill, or company, and a powerful tool to understand each asset's strengths and weaknesses, validated against several years of historical data on closures and survival. Learn more

-

Water Supply and Treatment

FisherSolve's Water Module shows water and wastewater flows for each mill. It includes data on volume source, application, destination, and treatment methods for each site's incoming water, outgoing wastewater, and sludge. This data can be used to measure water consumption per ton and compare it to the mill's water risk.

-

Carbon Emissions

Our Carbon Module shows the carbon output of every pulp line and paper machine for each of the products they produce. This tool provides information on carbon emissions of various scopes, all the way from cradle to destination. Users can measure and benchmark the carbon footprint of all players—helping customers measure ESG performance.

-

Production Data

FisherSolve provides information on machine, line, mill, and company production data covering all grades and finished products, furnish and fiber details, speed, width, trim, and asset descriptions.

Our platform describes products produced in hierarchies, separated by Major Grade, Grade, Finished Products, Bleached/Unbleached, Coated/Uncoated, On-Off-machine coating, and Machine PH to facilitate analysis of the over 500 paper and market pulp products.

-

Manufacturing Costs and Mass-Balance

Users can model every mill, pulp line, and machine's cost-of-production through FisherSolve's rich asset and raw material database to increase their understanding of mill operations with reliable insights into real-world modeled costs.

Our data-driven mass-energy balance engine delivers transparent results, detailing the costs of each machine and its products, rolling data up by level, including:

- Stage of the manufacturing process

- Line, mill, company, country, region, and global

- The finished product, grade, major grade, total

- Type of cost input

-

Capacity Trends

FisherSolve's Capacity Trends module allows users to analyze quarterly historic and announced actions for any grade and region segment in the industry.

Draw strategic-level conclusions with the ability to see how each machine's assets and production capacity have evolved.

-

Installed Costs

Replacement costs, also known as installed costs, are unique to FisherSolve.

With replacement costs of every major unit operation in every mill in the world, combined with our proprietary measure of assets' technical age, you can understand the magnitude of investment required to bring each asset up to current standards.

-

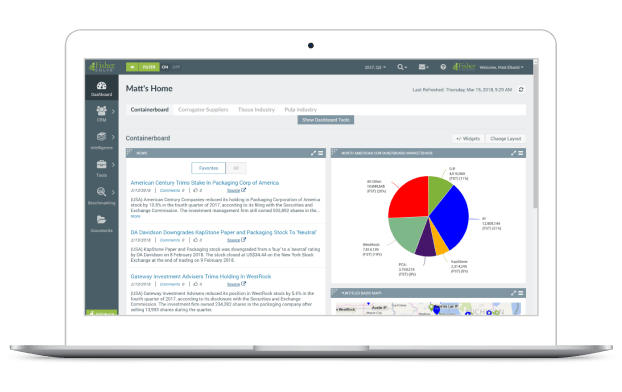

News and Projects

FisherSolve provides one of the most extensive paper industry news services, which users can use to their advantage and turn into actionable intelligence. Industry News delivers to subscribers' inboxes daily and covers capital projects, mergers and acquisitions, shutdowns and startups, financial issues, technology, market trends, and more.

We associate each news event with the mills, companies, regions, grades, and other subjects in FisherSolve, meaning you can read everything there is to know about a mill with a single click.

-

Market Optimizer

With Market Optimizer, gain valuable insights into global competitiveness and cost benchmarks, allowing faster and more profitable decisions. By providing a matrix view of a selected mill's performance in multiple locations, Market Optimizer helps users quickly identify valuable opportunities and maximize investments.

-

Virtual Mills

Our Virtual Mill feature allows you to create a confidential, user-defined mill that passes through Fisher's proprietary mass and energy balance model and can represent any greenfield, brownfield, rebuild, or grade change project.

Virtual mill inputs are defined by you with the Fisher consultant's expertise. The virtual mills are modeled with the same rigor as existing sites and the results - such as cash costs, energy consumption, or carbon emissions - can be visualized and benchmarked against existing sites and other virtual mills in FisherSolve.

Analysis of your virtual mill results can provide significant insights for decision-making as multiple scenarios can be evaluated.

Pave the Way for Sustainable Best Practices

Achieve Environmental, Social, and Governance (ESG) goals with our specially designed modules.

Users can evaluate the environmental impacts of mills with data on environmental flows, carbon footprint, and sustainability indicators, leading to effective reductions in water usage, waste generation, emissions, and energy consumption.

Make Strategic Decisions and Investment Plans

From evaluating existing mills, expansions, or new investments, we provide insights to make informed choices and maximize success in the industry.

Gain a Competitive Advantage with Market Insights

Perform in-depth analysis and benchmarking of individual mills with our extensive database. Users can compare production volumes, grades, product mix, costs-of-production, and other key metrics.

Identify growth opportunities and understand market dynamics to make strategic decisions that position you ahead of the competition.

Maximize Returns with Expert Guidance and Knowledge Building

FisherSolve supercharges knowledge-building by intuitively aggregating all tutorials, business cases, FAQs, glossaries, and reference materials directly related to your current search.

Additionally, our industry-leading consultants provide insight, coaching, and training to support a data-informed culture throughout your organization.

How We Power Your Business

FisherSolve can be scaled to meet your specific needs, making our platform a viable solution for any business working in or supporting the pulp and paper industry.

We have several solutions to choose from, whether you need to stay on top of your ESG goals with our environmental flow modules or lead your business to profitable and sustainable growth.

Access Global Mill Data and Analysis

Gain a competitive edge with access to detailed information on every pulp and paper mill in the world.

Analyze Current and Historical Pricing Data

Make informed pricing decisions with current and historical trend/time series data on all component prices.

Optimize Operations and Gain Efficiencies

Identify areas for improvement and streamline operations with the ability to analyze production trends, benchmark performance, and improve resource utilization.

Evaluate Sustainability Initiatives

Assess the environmental impact of pulp and paper mills to inform sustainability initiatives.

Make Informed Investment Decisions

Evaluate the long-term viability and financial health of mills with viability metrics and indicators.

Stay Ahead of the Market

Gain a comprehensive understanding of market dynamics and trends with the ability to compare production volumes, grades, product mix, cost-of-production, and other key metrics.