At the end of last year, Moody’s Analytics put out a list of the top 10 supply chain risks that companies face. These included:

- Poor supplier performance

- Demand planning complexity

- Global labor shortage

- Rising inflation

- A volatile global economy

- Complex sanctions and regulations

- Geopolitical risk

- Reputational risk

- Natural disasters and climate risk

- Cyber risk

Over the last few years, the global market has faced several of these factors at one point or another. And considering the Pulp and Paper industry is already such a volatile market on its own, throwing in detrimental impacts to the supply chain creates an undesirable and unpredictable environment. This affects producers, suppliers and investors all around.

Players in the industry are rethinking the risks of extended supply chain issues and where they should source. We’ve heard the same pain points from numerous customers in the industry. They reiterate the importance of and need for reliable information on the price structure of mills, the viability of mills, demand and capacity balance, and much more.

Here’s Where Fisher International Steps In

Fisher International can fill in the blanks to these questions with the use of our proprietary business intelligence platform FisherSolve. FisherSolve is a powerful, flexible and comprehensive solution designed by pulp and paper professionals for pulp and paper professionals.

With information on every pulp and paper mill in the world, FisherSolve provides users with the data necessary to make critical business decisions every day.

Need information on the viability of your mills? Our Viability Module was created to predict the long-term future of pulp lines and paper machines. Validated against several years of historical data on closures and survival, the result expertly evaluates the staying power of a given machine, mill or company. It also serves as a powerful tool for understanding each asset’s strengths and weaknesses.

Want to know the price structure of your mill? FisherSolve can provide you with substantial data on most of the necessary assets, production, cost, and industry insight needed in abundant detail for every pulp and paper mill and machine in the world. With this information, Fisher International can build resource and feedstock studies that can provide rapid and effective insights for your challenges.

Curious about how a new mill you’re thinking about building would do in the market? Our Virtual Mills tool allows you to create a confidential, user-defined mill that can represent any greenfield, brownfield, rebuild or grade change project.

All the inputs can be defined by the client and/or with Fisher consultants’ expertise. The virtual mills are modeled with the same rigor as existing sites, which means the results – such as cash costs, energy consumption or carbon emissions – can be visualized and benchmarked against existing sites and other virtual mills.

Data Is Just Numbers if You Can’t Strategically Analyze It

The truth of the matter is that data boils down to two critical points: its source and the people behind it.

Behind the information itself, you need industry experts to properly compile, organize and codify it. Otherwise, even the highest quality records won’t help you understand the industry, where it’s going and how to strategize your own planning.

Fisher International’s consultants offer decades of experience with a vast range of experience in the following areas:

- Broad market segments: We offer vital industry knowledge on tissue, containerboard, pulp, printing paper, packaging and more.

- Wide range of regions: We cover Europe, South America, North America and Asia.

- Extensive professional knowledge: Our experts cover all critical professional backgrounds such as business leaders, general managers, mill managers, and pulp and paper engineers.

What distinguishes Fisher consulting from any other service is our Leveraged Consulting approach, which increases the likelihood of delivering on your ROI targets.

Traditional consulting requires research and data assembly before any analytical work can begin. Conversely, our Leveraged Consulting approach allows for the substantial work to be done on day one of a project. This is because we utilize key data and analytic models found within our own business intelligence platform FisherSolve.

For more information on Fisher's Leveraged Consulting, download our white paper.

Let’s Look at a Hypothetical Case Study

To gain a better understanding of how Fisher can help you make high-stake decisions with confidence, let’s look at a hypothetical case study.

Suppose additional capacity of 300,000 mt/yr of linerboard using virgin fiber is added in Europe through the investment and installation of a new paper machine at an existing mill by our hypothetical company. The mill in question does not have enough pulping capacity, so it is assumed it will purchase part of the pulp needed.

What is the impact of this new investment?

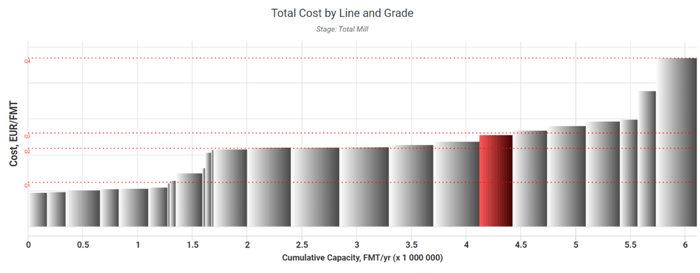

The benchmark cost curve below shows the manufacturing cost of the new machine against other European machines producing the same product grade. The cost position of the new machine (virtual mill), considering the assumptions made for its operations and furnishes, is within the 3rd quartile, meaning it’s not very cost competitive.

Source: FisherSolve

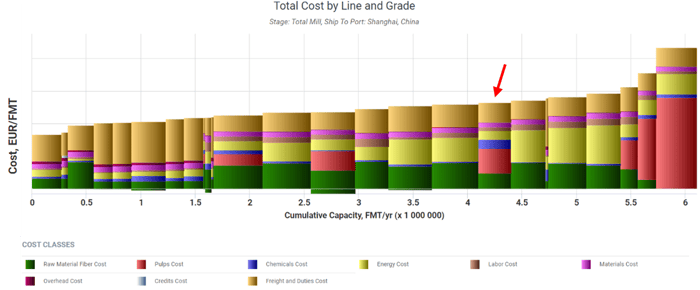

Source: FisherSolve

When including transportation costs to Shanghai, the 1st quartile mills become less competitive. By breaking down the manufacturing costs at the class level, we can see that purchased pulp and chemicals costs are driving the costs of the virtual machine up.

Source: FisherSolve

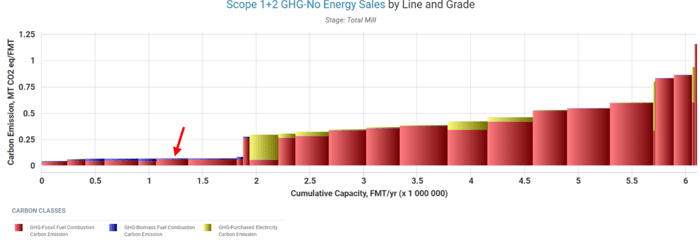

To round out our analysis, we would then evaluate greenhouse gas emissions for the virtual mill using our Carbon Benchmark module. The graph displaying Scope 1 + 2 emissions for the new machine versus its European counterparts shows that the new machine is among the lowest GHG emissions in the group. This is likely due to the selection of wastewood over fossil fuels as the energy source in the virtual mill, as well as internal generation of electricity.

Source: FisherSolve

Source: FisherSolve

With a clear understanding of the ‘big picture’ and the likely scenarios that would occur with this investment, our hypothetical company now has a better understanding of its future competitiveness. Meaning, business decisions regarding this investment can be made with a higher degree of certainty.

Learn More from the Experts at Fisher

When thinking ahead of how to best mitigate potential supply chain issues, data matters. Having access to such specific and crucial data, coupled with exceptional consulting services, will provide pulp and paper industry players with the leverage needed to excel above and beyond competitors.

For more information on how our services can benefit your company, talk to an expert at Fisher today.