A large number of paper mills use recovered paper as a major source for fibers. It’s generally assumed that making paper using recycled fibers saves energy compared to using virgin fibers, and various companies report energy savings anywhere from 30- 50 percent or more.

Given society’s growing focus on issues of energy and climate change, which kind of paper manufacturing is preferable – virgin or recycling?

With the current spotlight on climate change, saving energy is assumed to result in reduction in greenhouse gas emissions (GHG). GHG emissions are closely linked to overall energy usage, but also depend on types of fuels used.

This blog compares energy usage and GHG emissions at a select group of paper mills worldwide that produce packaging grades. Note, this analysis is within the mill only and does not consider the GHG associated with collection and processing of recycled fibers.

The analysis is based on insights from Fisher International’s FisherSolve™ Next platform. Fisher International maintains a comprehensive database of paper mills across the globe producing more than 50 tons of paper per day. FisherSolve™ Next contains detailed process-equipment and production data for about 3,500 paper mills around the world.

The grade of paper manufactured dictates manufacturing process and overall energy usage. So, any valid comparison must be made between mills making similar grades of paper.

Total energy usage in this article is calculated by combining energy in fuels used for combustion and purchased electricity. For comparing mill sites, total energy usage is expressed in gigajoules (GJ) per finished metric ton (FMT).

Packaging grades selected for comparison:

- Linerboard mills using virgin pulp and/or recycled fiber

- Corrugated Medium mills using virgin pulp and/or recycled fiber

Linerboard Mills:

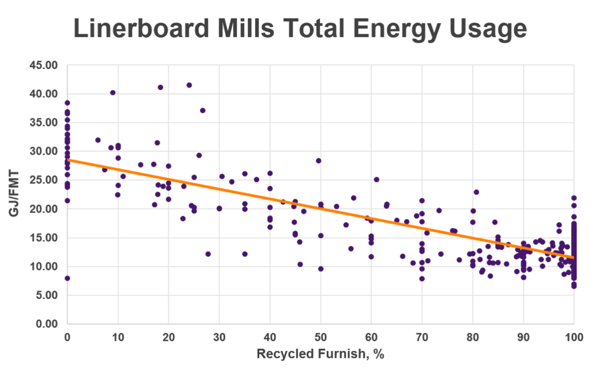

There are 740 mills worldwide in this category. Twenty-five mills are virgin integrated and do not use recycled fiber, and 532 mills use 100 percent recycled fibers. The remainder use a combination of virgin and recycled fibers. Energy usage for all linerboard mill sites is shown below:

Source: FisherSolve™ Next

Source: FisherSolve™ Next

The trend in energy savings is obvious with increase in recycled content. The average energy savings worldwide for linerboard mills is 60 percent (illustrated in the chart below). Energy efficiency variation is similar for virgin and 100 percent recycled mills.

Source: FisherSolve™ Next

Source: FisherSolve™ Next

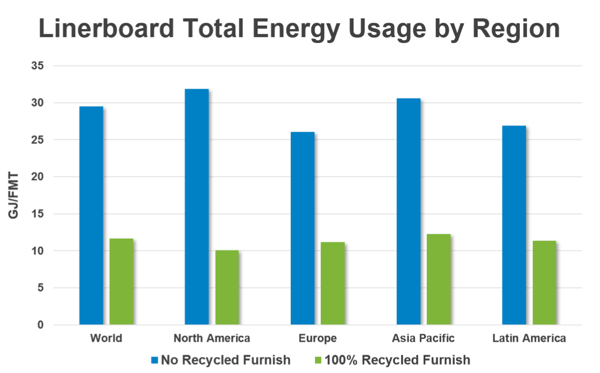

Total energy usage by region for virgin vs. recycled mills is below. The energy savings are similar in all regions.

Source: FisherSolve™ Next

Source: FisherSolve™ Next

Corrugated Medium Mills:

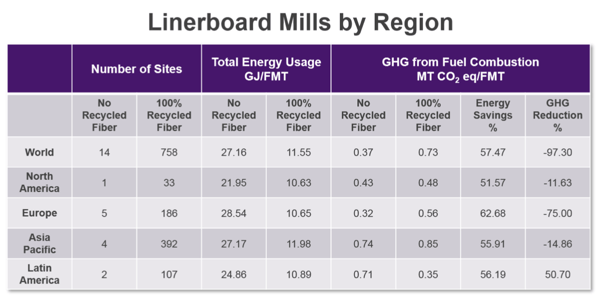

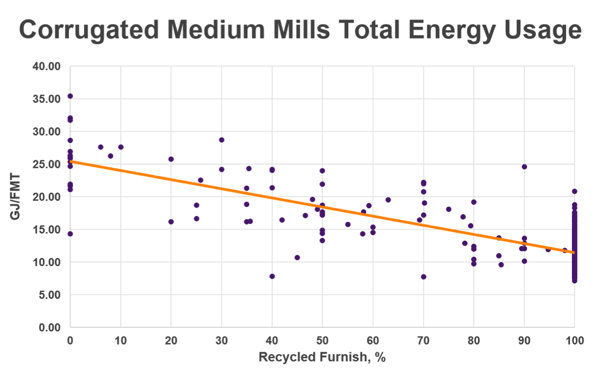

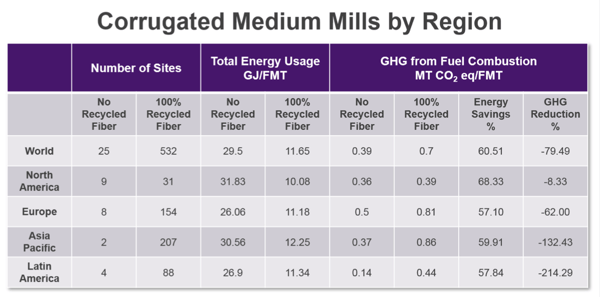

There are 839 mills worldwide in this category. 14 mills are virgin integrated and do not use recycled fiber, while 758 mills are based on 100% recycled fibers. The remainder use a combination of virgin and recycled fibers. Energy usage for all corrugated medium mill sites is below:

Source: FisherSolve™ Next

Source: FisherSolve™ Next

The trend in energy savings is obvious with increase in recycled content. The average energy savings worldwide is 57 percent for corrugated medium mills (illustrated in the chart below). Energy efficiency variation is similar for virgin and fully recycled mills.

Source: FisherSolve™ Next

Source: FisherSolve™ Next

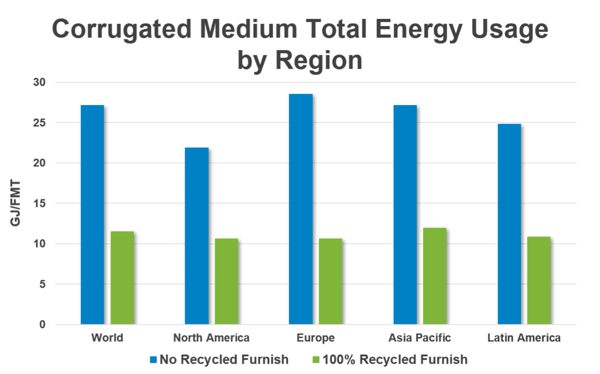

Total energy usage by region for virgin vs. recycled mills is below. The energy savings are similar in all regions.

Source: FisherSolve™ Next

Source: FisherSolve™ Next

Conclusion:

As in much of life, the answer to the question, “Which is better?” is not a simple, “A” or “B.” It is nuanced.From the standpoint of total energy used, recycled fiber certainly results in energy savings at paper mills. The energy savings are very high (close to 70 percent) for packaging grades.

Of course, some virgin manufacturing is required in the economy or there would be no paper to recycle. So, the right question isn’t really: “Which is better?” Better questions might be:

- How much should society encourage of each?

- Given all the pressures on a business, such energy costs, potential regulations, investment needs, etc., which is better for my business?

To see a similar analysis for mills producing printing/writing and newsprint grades, download the full Fisher analysis “Paper Recycling Energy Savings and GHG Reduction - Myth or Reality?” by clicking the box below.