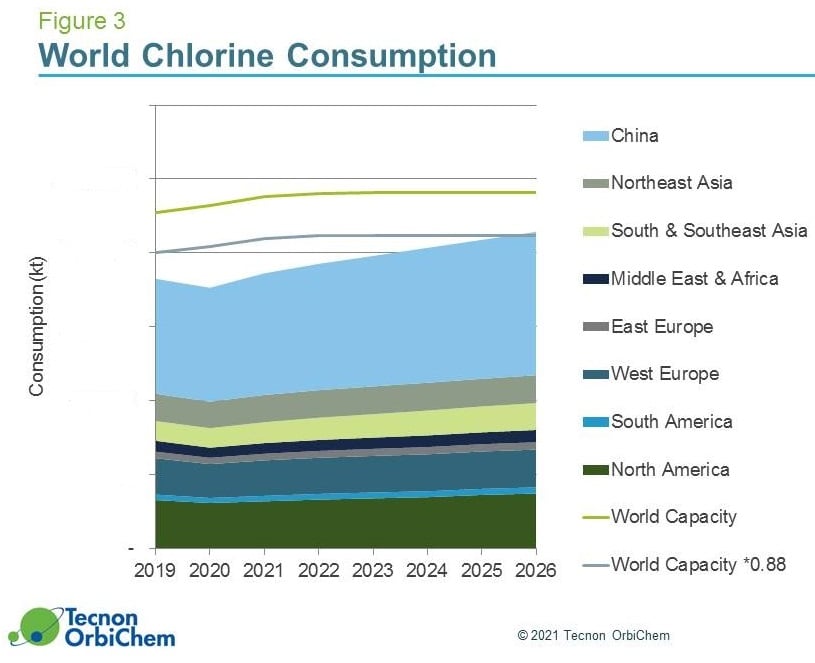

The market has tightened substantially since Hurricane Ida hit the US in August. Demand for caustic soda has recovered faster than expected, however, production in the country was negatively impacted by weather-related issues as the supply of chlor-alkali products has struggled to recover since the Deep Freeze in February. Currently, the output of caustic soda is improving but producer inventories are low and there are still minor production issues in the US.

The Shintech expansion at Plaquemine, Louisiana is due to come online in Q4 2021, which may help to ease the supply tightness. However, four chlor-alkali plants in the US have been taken offline since the beginning of 2021. Olin announced plans to permanently shut 20% of its chlor-alkali capacity at Plaquemine, Louisiana as well as shutting 200 ktpa diaphragm tons at McIntosh, Alabama, and 230 ktpa diaphragm tons at Freeport, Texas. OxyChem also closed its 162 ktpa Niagara Falls, New York plant due to unfavorable regional market conditions. The Shintech plant expansion will take a few months to ramp up to full capacity, and there is more capacity reduction this year than capacity coming online. This, combined with the robust demand in all major sectors, means that it is unlikely that the supply and demand of caustic soda will rebalance in 2021.

Global export prices have risen significantly since the hurricane hit, worsened by reduced production in Europe and Southeast Asia as well as energy controls and environmental inspections affecting Chinese production. There have been reports of a European producer lowering operating rates as a result of high energy costs prices. It is quite unlikely that other producers will follow due to the high European demand and the global shortage of caustic soda, however, the skyrocketing energy costs are putting a lot of cost pressure on producers, resulting in higher caustic soda prices.