Understandably, global economic circumstances are at the forefront of daily business decisions right now—especially in the manufacturing sector, which oftentimes has a limited ability to quickly react to market signals.

It is a daunting prospect to plan for new or expanded projects in the current environment, yet visionary industry leaders are looking beyond the uncertainty and well ahead of the temporary downturn we find ourselves in. As consulting firm McKinsey & Company wrote in the wake of the Great Recession, “Manufacturers should view today’s environment as an opportunity. Now they can make changes—renegotiating contracts, consolidating manufacturing and distribution networks, launching aggressive productivity programs—that might not have been feasible earlier and may soon be difficult again.”

Constant Improvement Drives Strategic Advantage

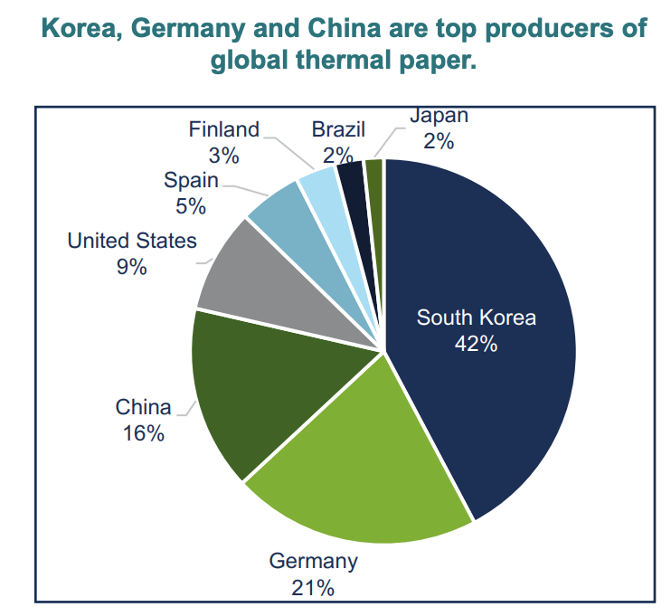

One of the foundations of lean manufacturing is the Japanese concept of Kaizen, a striving for continuous, daily improvement. Continuous improvement is a comprehensive concept that requires meticulous attention to detail and nimble operating procedures to sustain. For participants in the pulp and paper supply chain—which is diverse and susceptible to the effects of myriad market variables—lean manufacturing can bring tangible value and improve strategic positioning and profitability.

Reliable business intelligence is what differentiates a Kaizen-based strategy from a reactionary lurch during periods of uncertainty. For instance, the improvement cycle associated with the renowned Six Sigma process methodology begins with a concrete procedure:

- Define: Identify the problem and define the scope of improvements

- Measure: Collect business data

- Analyze: Conduct root cause analysis

- Improve: Develop potential solutions and evaluation criteria

- Control: Monitor progress and make adjustments

Just as Kaizen represents the continuous practice of improvement, Fisher International is dedicated to serving participants in the global pulp and paper supply chain as an industry expert and trusted business partner with a focus on helping our clients drive superior, sustainable performance. To assist in this process, Fisher provides:

- Unmatched dedication to customer service, product support and developing meaningful relationships as a long-term partner

- Transparent and consistent enterprise pricing

- An easy-to-use interface

- One-stop shop for pulp and paper asset information as well as cost, carbon, energy and viability benchmarking

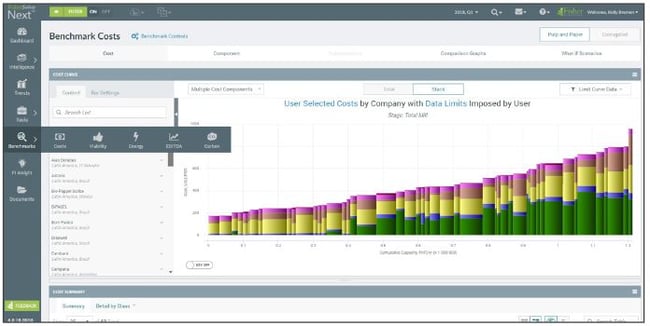

- The most granular cost benchmarking available

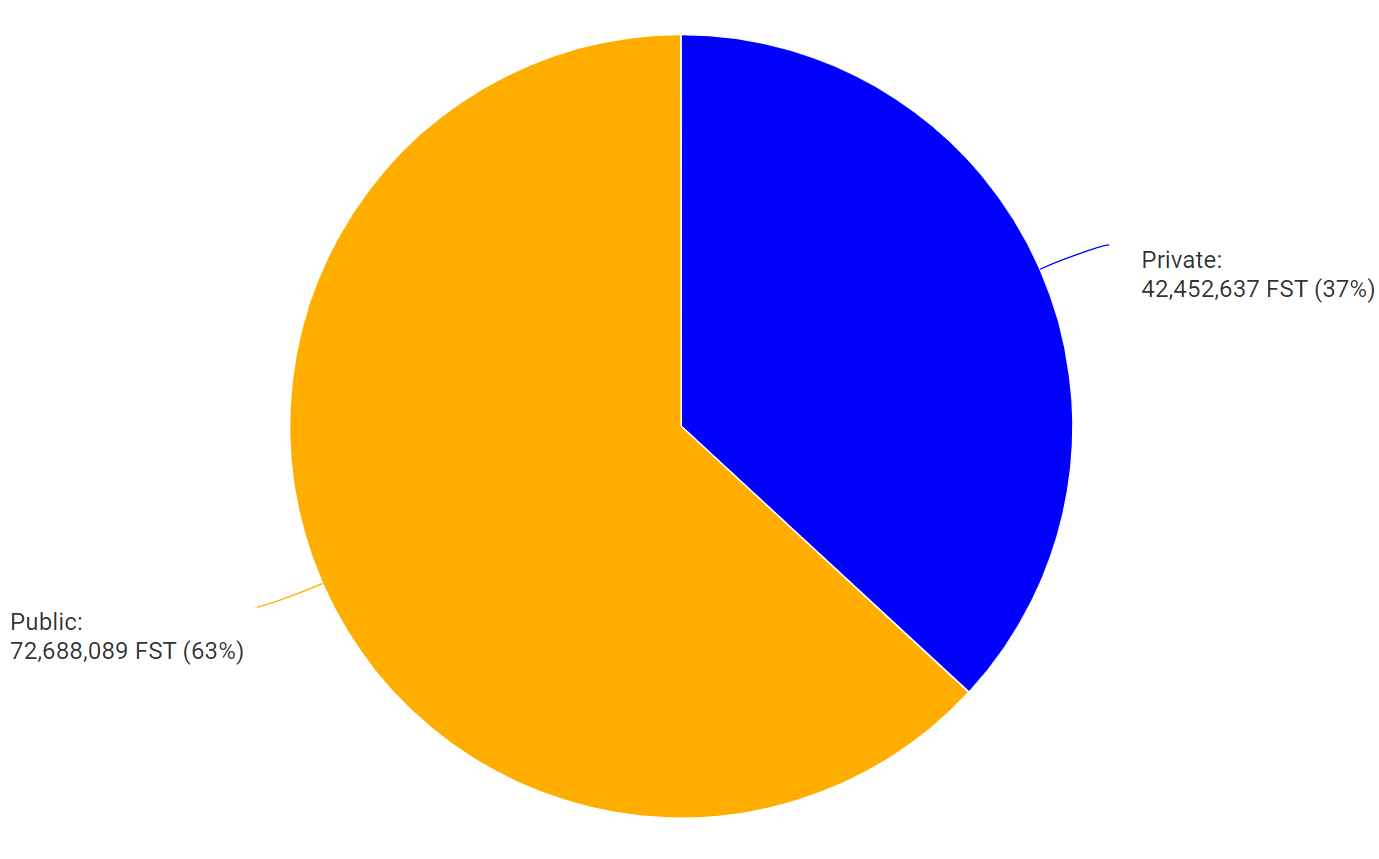

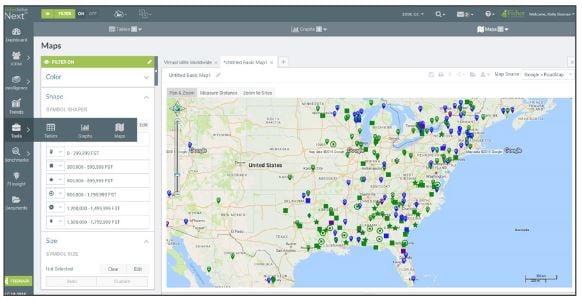

FisherSolve™ is a business intelligence system designed to provide the kind of powerful, granular data needed to confidently improve your decision-making and performance on an ongoing basis. FisherSolve™ contains highly detailed and complete information on every pulp and paper mill in the world, and it describes the assets, production, operations, environmental flows, costs-of-production, long-term viability, carbon footprint and more for all pulp and paper mills producing 50+ TPD.

Because this is the only database with integration and true data transparency for every mill, line and machine, you can drill down to the details that differentiate each mill and roll the details up for strategic analysis. FisherSolve™ can surface the data that people throughout the pulp & paper supply chain need each and every day. The result is faster, more timely access to the kind of business intelligence that will inform your critical decisions.

FisherSolve’s flexible web-based platform design takes data, integration and analysis to a new level. And because the platform is scalable, it allows companies to tailor its capabilities to their specific needs, making it a viable solution for businesses working in or supporting the pulp and paper industry.

- Dynamic graphing

- Intelligence

- Insightful tools

Available in ten languages, it will ensure your people, no matter where they are located across the globe, can take advantage of all it has to offer.

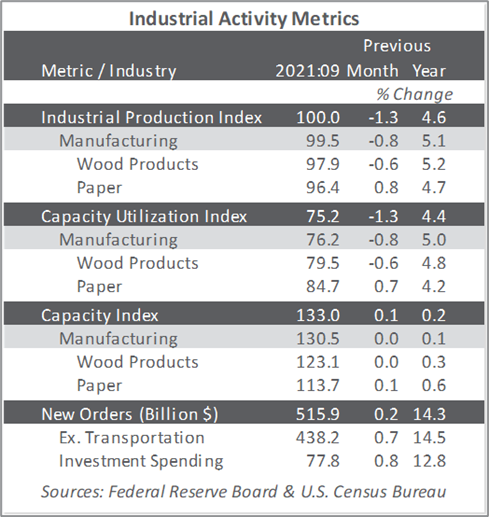

We believe that the continual process of evaluation and goal setting using the strategic application of reliable datasets is the most effective way to succeed in the present while planning for the future. Constant analysis of valuable market intelligence is imperative to minimizing costs and maintaining profitability in a highly fluid and volatile market.