As Dwight Eisenhower famously remarked: “In preparing for battle, I have always found that plans are useless, but planning is indispensable.”

Gen. Eisenhower came long before this COVID-19 pandemic, but he understood the difficulty of planning with incomplete information. Having a plan, even if it involves wrong assumptions, provides the best understanding and ability to react to events that unfold.

As we continue to navigate toilet paper-hoarding habits and disruptions in tissue production and distribution, the demand for public handwashing support in this new normal could increase significantly.

This article explores how that might drive changes in paper hand towel production and distribution as we come out of global lockdown and get back to business.

How Clean Are We, Really?

The COVID-19 pandemic has brought a new focus on cleanliness and preventing the spread of disease through personal contact and contaminated surfaces. We have experienced epidemics like this in the past, but SARS, MERS, and ZIKA receive global only had a regional impact. Ebola caused worldwide concern, however, none of these events had enough global impact and personal disruption to significantly change Individuals handwashing behavior.

Tissue makers focused on the commercial or the away-from-home market have long understood that hand washing and drying with a paper towel is an underserved market need. If people followed professional guidelines (as shown in Figure 1 from the Centers for Disease Control and Prevention) there would be a significant increase in paper hand towel demand.

There are two problems with this simple recommendation -- not everyone washes their hands, and those who do rarely take the prescribed time to do so properly.

A 2003 study by the American Society for Microbiology found 83 percent of women washed their hands after using the restroom, but only 74 percent of men did the same. And this isn’t unique to the US as a British study conducted in highway service station restrooms, using electronic sensors to measure compliance found that 65 percent of women and 35 percent of men washed their hands.

There are many reasons why people don’t clean their hands. It’s probably most difficult in a medical setting (where washing is required after each patient interaction) than in food processing where the work is continuous. Frequent hand washing can irritate skin and cause topical infections. Public restrooms are not always clean and some try to get out as fast as possible without stopping at the sink.

We don’t know what life in the post-pandemic world will be like, but it’s reasonable to expect some changes to our routines and behaviors that will be permanent.

We are now very aware that soap and water destroy the virus with no need for anti-microbial additives. Hand sanitizer has some efficacy but isn’t a complete answer to removing soiled material or killing other resistant germs like the gastrointestinal norovirus.

So those in the tissue and towel industry have to ask themselves:

- What if this pandemic results in a sea-change in handwashing compliance and frequency?

- What if patrons of restaurants, hotels, and truck stop all demanded better hygiene facilities?

- What if people started washing their hands after touching public handrails and buttons?

- What if more people head to the washroom after arriving at a destination or consuming food or drink on the go?

- If hand washing habits truly change, how will we dry our hands?

The two common alternatives for tissue products when it comes to drying one’s hands are cloth towels (typically used at home) and the dreaded air dryer commonly found in public restrooms.

Most people start these air dryer units, give up, and walk out while wiping their hands on their pants. So why do proprietors and building managers install these dryers if no one likes them? It comes down to space utilization. They can avoid storing paper towels and taking care of wet paper towel waste.

To be fair, electric hand dryers have improved. Several hand dryers have emerged with high-velocity air that can successfully dry hands in about 10 seconds. Finally, air dryers are useful for the first time. These dryers suggest using electricity is a benefit because it reduces paper towel consumption. But why is this a benefit and who is benefiting? The coal plant producing the electricity?

Now with hygiene and hand washing at the forefront our daily lives, we understand air dryers create conditions for cross-contamination and defeat the purpose of hand washing.

In a report published in the respected Mayo Clinic Proceedings (2012 Aug; 87(8): 791–798.), the authors state that:

“From a hygiene viewpoint, paper towels are superior to electric air dryers. Paper towels should be recommended in locations where hygiene is paramount, such as hospitals and clinics. … Many studies have found friction to be a key component in hand drying for removing contamination. Bacteria were removed from washed hands by the mechanical abrasive action of drying with paper towels. And microbiological testing of the paper towels after use indicated that many bacteria were transferred from the hands to the paper towels.”

How Will Post-Pandemic Towel Production Respond?

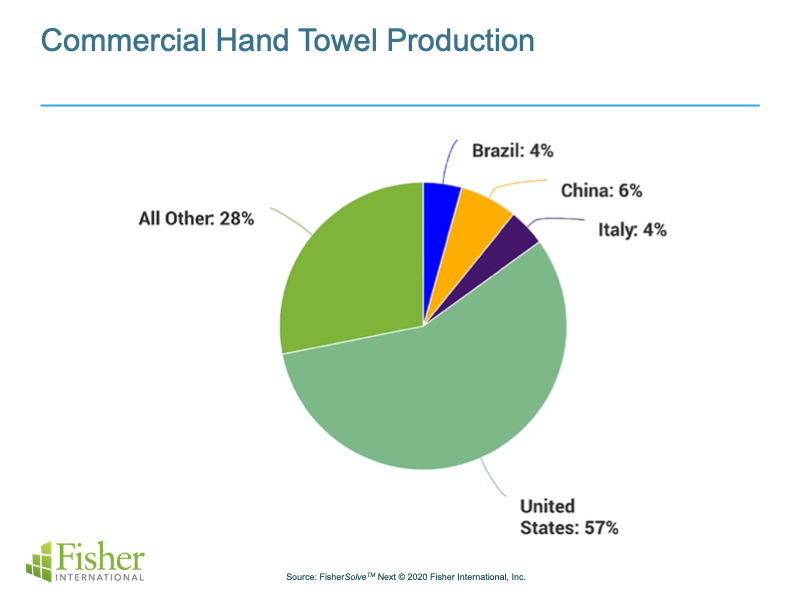

Figure 1 shows the global commercial hand towel production capacity for the top four producing countries. Going into the first quarter of 2020, we see the United States produces 57 percent of all commercial hand towels. This provides the opportunity to use the US as a test case for modeling potential demand changes after the pandemic passes.

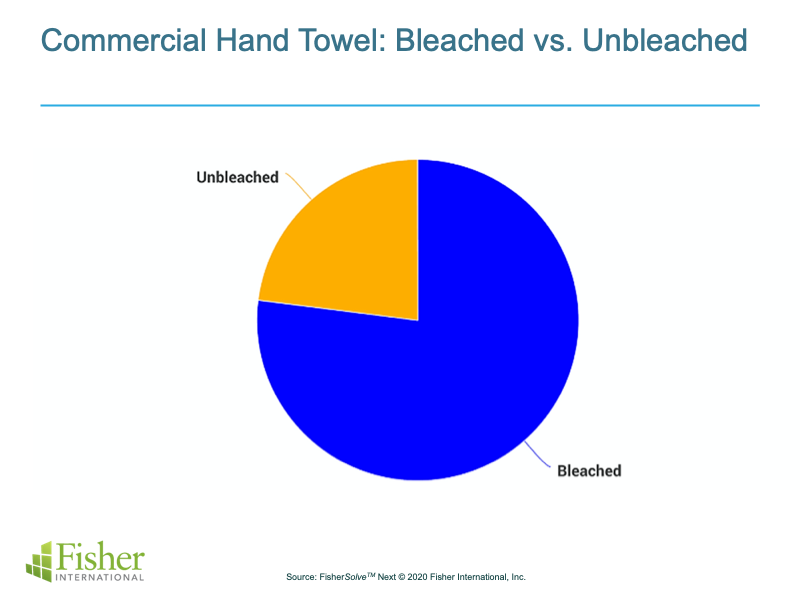

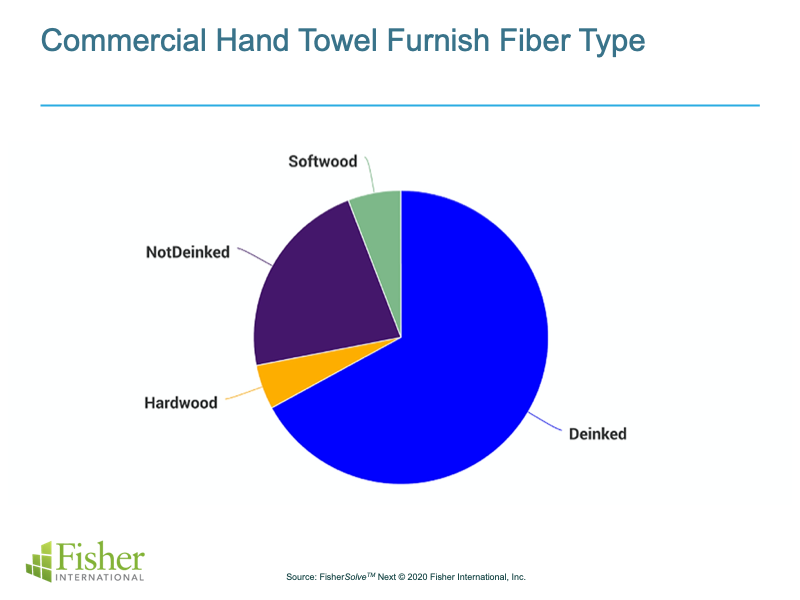

The American hand towel market covers a wide range of quality. Slightly less than a quarter of all towels are still the plain unbleached, brown, wet-creped sheets that have long been the low-price product. Figure 2 shows the bleached and unbleached fiber breakdown, and Figure 3 shows that about 85 percent of the total volume is made from recovered paper.

The American hand towel market covers a wide range of quality. Slightly less than a quarter of all towels are still the plain unbleached, brown, wet-creped sheets that have long been the low-price product. Figure 2 shows the bleached and unbleached fiber breakdown, and Figure 3 shows that about 85 percent of the total volume is made from recovered paper.

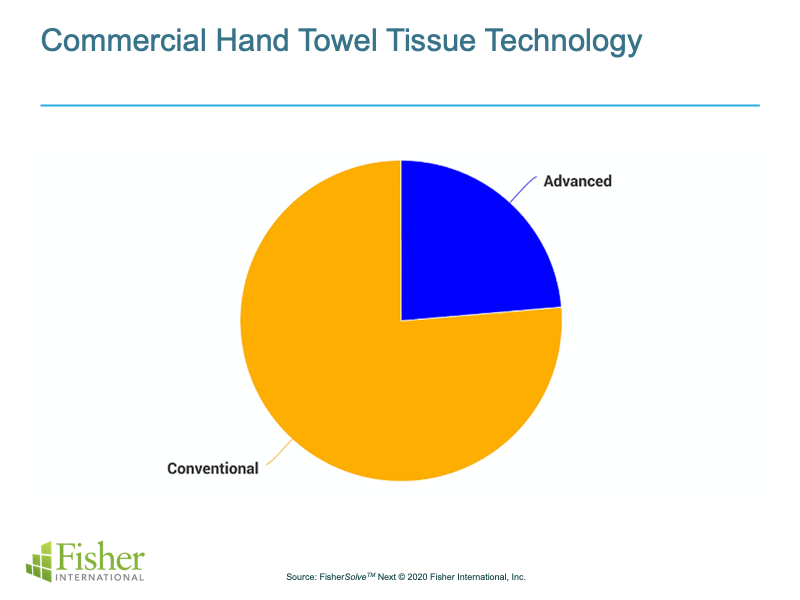

Figure 4 shows almost 25 percent of hand towels used in the United States are produced with TAD or some other form of advanced tissue technology to create improved softness and absorbency. This is a trend that grown as building owners/managers try to offer upgraded service for important clients. This included most truck stop chains across the US Interstate Highway System.

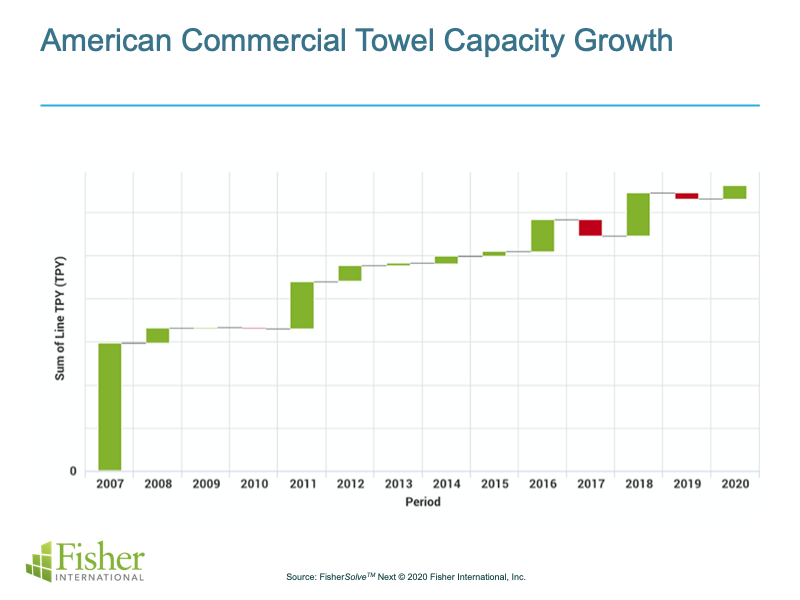

American hand towel capacity grew at a CAGR (compound annual growth rate) of 6.5 percent from 2007-2019. The capacity additions shown in Figure 5 include grade changes, rebuilds, and new machines over that period.

A small consumer behavior change in response to the pandemic could be a step change in demand of 10 percent, requiring two new large tissue machines. If people were to make significant changes in utilization of facilities and toweling, a 30 percent increase in demand (requiring nearly six new tissue machines) is realistic.

A small consumer behavior change in response to the pandemic could be a step change in demand of 10 percent, requiring two new large tissue machines. If people were to make significant changes in utilization of facilities and toweling, a 30 percent increase in demand (requiring nearly six new tissue machines) is realistic.

The impact on the tissue business would be large, but American tissue producers have been quiet on the issue in the past, unlike European producers.

Maybe this time is different. Tissue makers should be proud of the role they play in public health and willing to promote the products.

Bruce Janda has over 40 years of experience in the paper and non-woven industry, specializing in tissue and towel products and processes, from concept through manufacturing and commercialization. Bruce has a BS in Chemical Engineering from Michigan Technological University and earned his MBA from the University of Wisconsin. He is a TAPPI Fellow, holds 19 US tissue and papermaking patents, and writes a regular column for Tissue World Magazine.